POWER CONNECT

Explore the latest ways people are integrating John Deere power solutions.

Explore the latest ways people are integrating John Deere power solutions.

EMERGING TECHNOLOGIES

See how John Deere is making significant investments in diversified power solutions with Kreisel Electric.

EMERGING TECHNOLOGIES

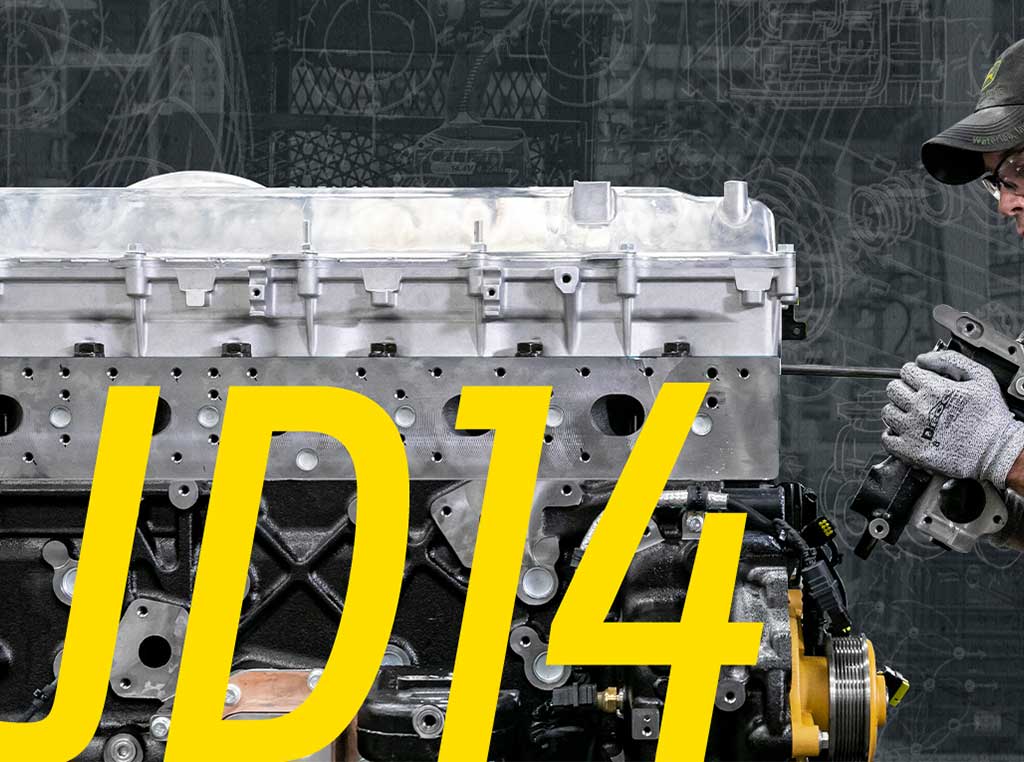

We designed the JD14 engine with reliability and durability at its core, so you can count on it to perform in the extremes of rugged, off-highway applications.

EMERGING TECHNOLOGIES

The first in a planned refresh of the diesel engine product line, the JD14 engine was created specifically to meet customers' needs for increased reliability, durability, and serviceability.

INDUSTRIAL

See why a John Deere industrial engine was the right solution to deliver the horsepower needed to power Michael Byrne Manufacturing’s auger boring machine.

INDUSTRIAL

See how Neuson Forest's steep slope harvesters utilize the rugged, reliable power of John Deere industrial engines to take on tough timber harvesting jobs.

INDUSTRIAL

See why a John Deere 6.8L engine was the right solution for BCU's industrial water pump when the company encountered a supply hurdle.

MARINE COMMERCIAL

A repowered Gulf Star serves oceangoing vessels along the Texas Gulf Coast.

MARINE COMMERCIAL

When charter boat Sydneysider needed a new marine diesel engine, the vessel's owner found success with John Deere. See why it was the perfect fit.

MARINE COMMERCIAL

Dolpower and John Deere worked together to help inland waterway skippers meet Stage V emission standards.

MARINE RECREATIONAL

See how Sunreef Yachts customizes its catamarans and sets new superyacht standards for design, comfort, and finish — all powered by John Deere marine engines.

MARINE RECREATIONAL

See how a John Deere marine diesel engine provided better fuel economy, power density, and reliability to the Emerald Lady motorsailer on the Caribbean.

MARINE RECREATIONAL

See why these boat owners relied on their John Deere marine engine distributor to choose the best 4-cylinder marine engine for higher horsepower and lower rpm.