Integrating Renewable Fuel Technologies

Emission regulations are an ever-present concern for equipment manufacturers and customers within all industries. As owners and operators of off-highway equipment continue to face ever-increasing demands for lower emissions and higher fuel economy, John Deere is making strategic investments in a diversified range of powertrain solutions to support its customers in future-proofing their equipment operations. This includes investing in viable renewable fuel solutions that can address customers' pain points and give them a competitive edge in the off-highway market.

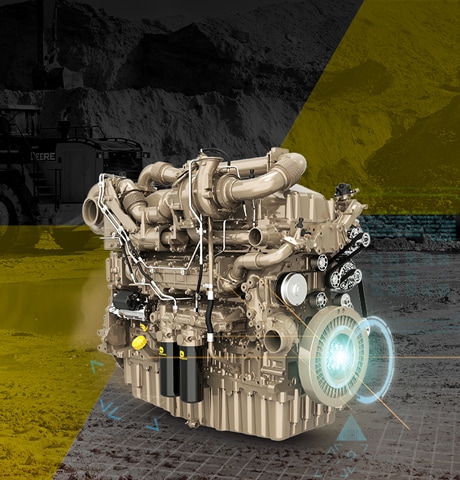

With world-class engineering expertise, John Deere is simplifying the integration of renewable fuels with combustion engines to deliver more value and productivity.

Renewable Fuel Compatibility with John Deere Engines

Petroleum-based fuels have been the industry standard for years. This is primarily due to the lack of acceptable, cost-effective, and reliable alternatives. However, with growing interest in sustainable energy, renewable fuels are becoming more widely adopted and readily available.

John Deere considers biodiesel and renewable diesel fuel to be the most promising options for integration into the off-highway equipment industry.

John Deere engines can use biodiesel:

- Stage V engines operated within the European Union can use biodiesel blends up to 8% (B8).

- Final Tier 4/Stage IV and Interim Tier 4/Stage III B engines can use biodiesel concentrations up to 20% (B20).

- Tier 3/Stage III A and lower tier engines can use up to 100% (B100) biodiesel.

- Biodiesel must meet the standards set by the American Society of Testing Materials (ASTM) D6751 or European Standard (EN) 14214.

John Deere engines can use renewable diesel fuel (such as HVO):

- Renewable diesel fuel (paraffinic diesel fuel) can be blended with petroleum diesel or used at 100% (RD100).

- Renewable diesel fuel must meet the standards set by either ASTM D975, EN 590 or EN 15940.

The use of biofuels such as ethanol, biodiesel, and renewable diesel fuel can contribute to significant CO2 reductions on a well-to-wheel basis. John Deere is continuing to explore new technologies that incorporate advanced combustion for continued compatibility with renewable fuels.

Biodiesel

Biodiesel is a renewable, oxygenated fuel made through transesterification of a variety of renewable resources such as vegetable oils (soybean, rapeseed, etc.) and animal fat. It can be blended at any level with petroleum diesel to create a biodiesel blend. As a renewable, domestic energy source, biodiesel can help reduce dependence on petroleum imports.

Renewable Diesel Fuel

Renewable diesel fuel is a paraffinic fuel made by either hydrotreatment of renewable resources such as vegetable oils (soybean, rapeseed, etc.) and animal fat, or through a synthesis process such as gas-to-liquids (GTL). These biofuels offer a sustainable replacement for petroleum diesel fuel with comparable performance.

Ethanol

Ethanol is a renewable fuel made from corn and other plant materials. Ethanol is widely used in spark-ignition engines, with the most common blend being E10 (10% ethanol, 90% gasoline). With some engine modifications, ethanol can potentially be used as a fuel in compression-ignition engines.

Because of advancements being made in a variety of renewable fuel types, compression ignition engines have a long life ahead.

Want More Information?

Find answers regarding engine emissions, service requirements, and other commonly discussed topics.