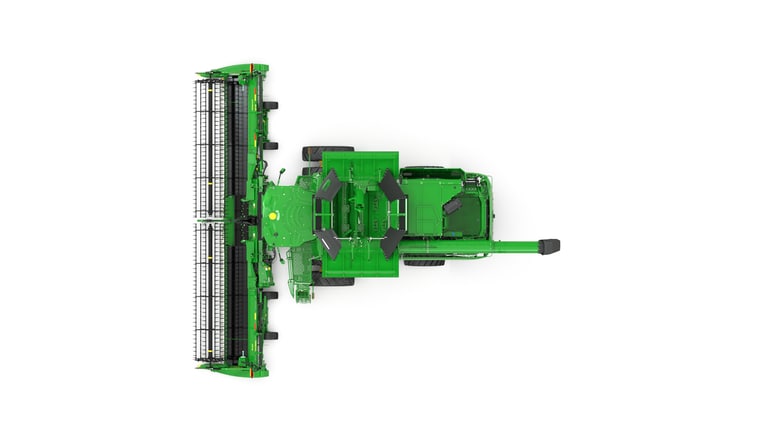

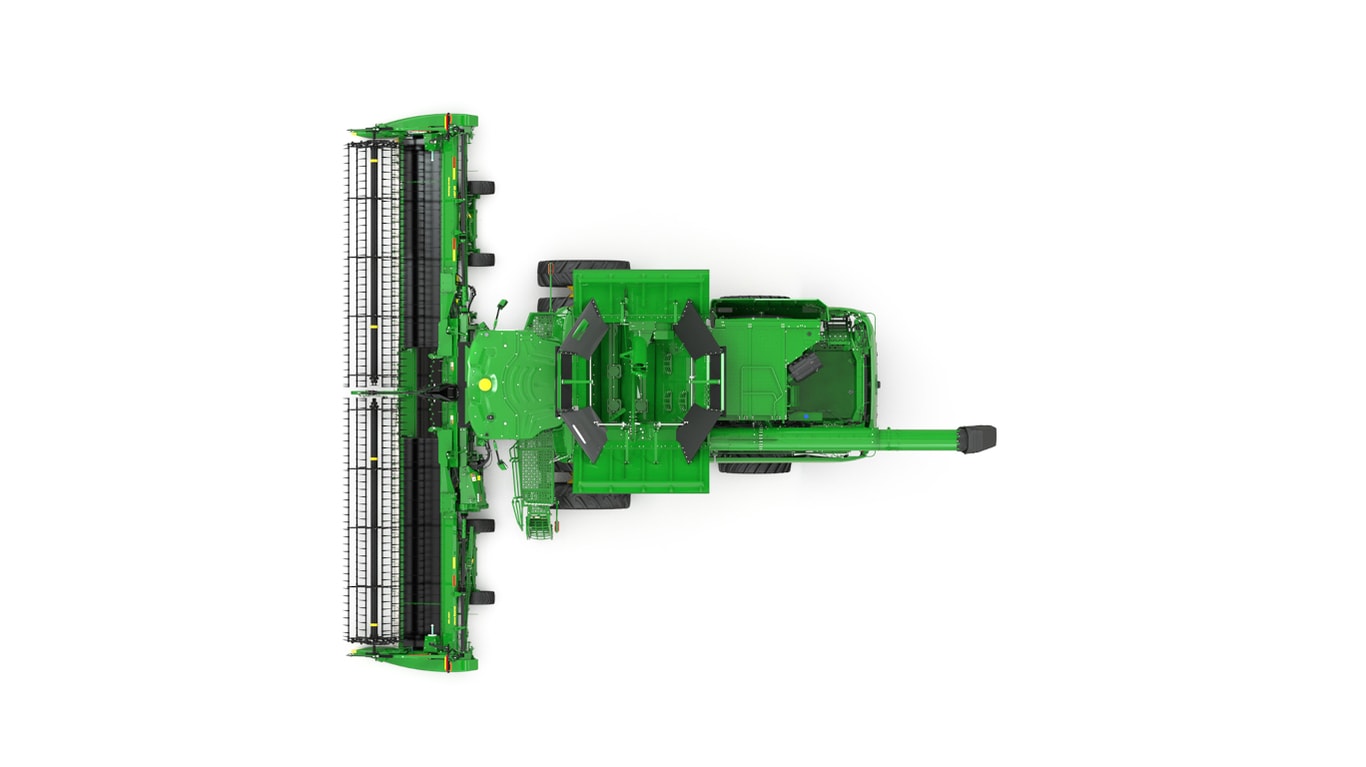

Harvesting in wheat

Harvesting in wheat

Truly tough conditions demand more than simple solutions. Rather than slightly improve performance in rice, canola, wheat, barley, oats, or other tough small grains, John Deere S7 Combines set new capacity standards with four crucial components: Active Concave Isolation, a high-performance feeder house, heavy-duty interrupter grates with integrated interrupters, and the variable-stream rotor. When you’re looking at a storm on the radar and you don’t have time to spare, you can run full throttle and still put your toughest crop into the machine without any issues.

- Better material handling – The industry-exclusive variable-stream rotor features a longer, more tapered front cone design that excels in wet, green rice or small grains where the straw is especially tough. The variable-stream rotor with adjustable top cover transport vanes is recommended for rice producers and those facing tough threshing conditions. The vane angle can be adjusted to reduce the stress on straw material as it flows around the rotor, increasing the quality of the straw while using less fuel. Along with the tough material handling capabilities of the variable-stream rotor configuration, the straw quality and length can be improved due to the electrically adjustable top cover transport vanes.

- Dyna-Flo™ Plus cleaning shoe provides more cleaning capacity – In shoe-limited conditions, you’ll see a 14 percent capacity boost in wheat and canola compared to previous John Deere designs, raising your productivity and improving grain quality. Simply put, this is a cleaning system that does it all.

- Harvest through the toughest conditions – Active Concave Isolation (only available on S7 800 and S7 900 Combines) has been improved by applying hydraulic pressure to better secure the concave, providing extra stability when harvesting really tough crops. This increases the machine capacity by 10 percent, so you can harvest outside the optimal harvest windrow or crop conditions when necessary.

- Better feeding in tough conditions – The S7 Combine feeder house design features an exclusive pivoting mid-frame design to provide the highest level of material handling and feeding capacity, especially in high-volume, tough crop conditions. The front feed drum provides you with 5.1 cm (2 in.) of additional movement for greater flexibility in challenging crop.