Access all the tools you need to help diagnose your John Deere equipment’s issues fast

Access all the tools you need to help diagnose your John Deere equipment’s issues fast

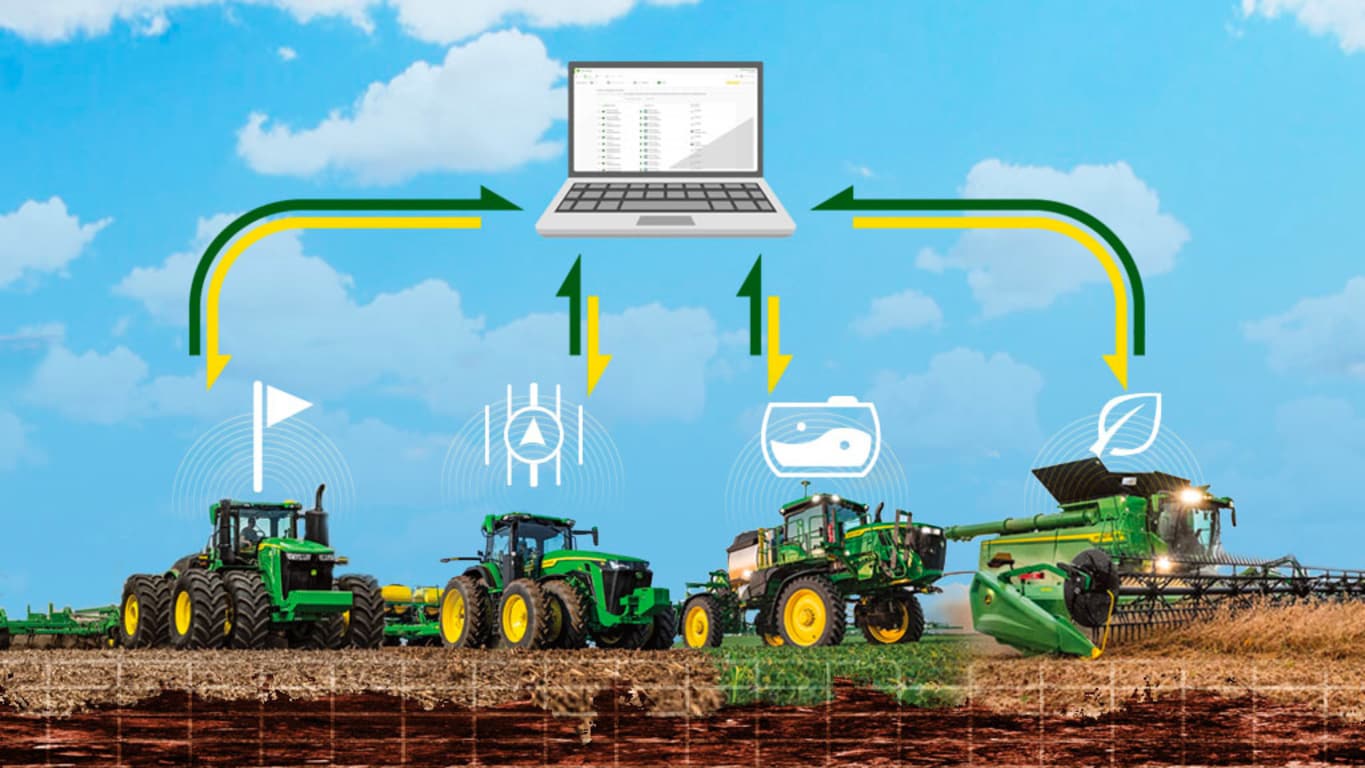

The John Deere Operations Center™ PRO Service one-year license further empowers you to keep your entire fleet running at its best with the information you need. Run it your way – when issues arise, use the powerful tools below to quickly diagnose your machines so you can quickly get them back to running at their best.

- View service insights for all your licensed machines in one easy view with Fleet View

- View a variety of machine data points with diagnostic information

- Address potential issues before they become more problematic with Machine Health Insights

- Quickly find the information you need with AI-enhanced search across operators' manuals and all technical manuals

- Interact with a digital schematic of compatible machines’ electrical systems

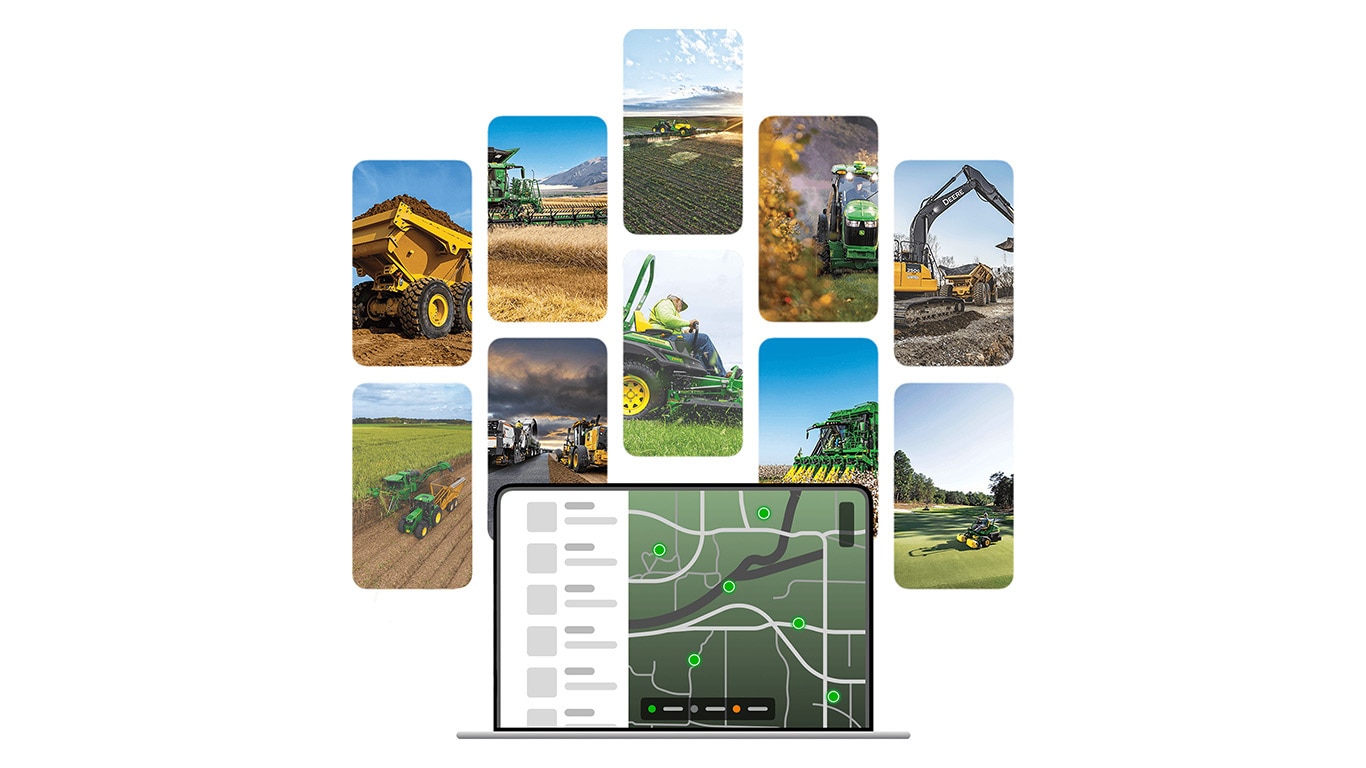

Fleet View – View service insights for all your licensed machines

View your whole fleet with the quick overview from Fleet View

View your whole fleet with the quick overview from Fleet View

You’re checking your fleet before a busy week. Instead of jumping between systems, you open one page and instantly see which of your John Deere machines needs attention—whether it’s a pending software update, Product Improvement Program (PIP), or an upcoming maintenance interval. Every machine page brings together the key details you need—license status, Operations Center organization, engine hours, maintenance plan status, active Product Improvement Programs (PIPs), diagnostic trouble code (DTC) count1, warranty status*, available software updates, and machine health insights—all tied to your machine’s PIN. It’s everything in one place, ready when you are.

Decide which machines to prioritize, how to plan your repairs, and when to take action. All the insights you need are right in front of you, so you can keep your operation moving.

*Always check your actual license and warranty contracts for details, exclusions, and limitations.

Diagnostic Information – View a variety of machine data points

Review, refresh, and clear Diagnostic Trouble Codes all in one spot

Review, refresh, and clear Diagnostic Trouble Codes all in one spot

You’re mid-operation when your machine throws a code. Instead of guessing what’s wrong, you open Operations Center PRO Service and get straight to the source. View, refresh, and clear Diagnostic Trouble Codes (DTCs)1. Run limited tests and calibrations5. Record live data and share it with your technician, if you choose to. Whether the issue is resolved on the spot or needs a deeper look, you’re in control.

Run it your way with the tools to diagnose, document, and decide what happens next, Operations Center PRO Service was designed to reduce guesswork and increase uptime.

Machine Health Insights – Address potential issues before they become more problematic

Check out the Monitor tab and see Machine Health Insights

Check out the Monitor tab and see Machine Health Insights

You’re not always in the cab—but your machines can keep you in the loop. Connected equipment with remote monitoring3 can flag potential issues as they develop—giving you a clear view of what’s happening, what it means, and what actions to take7.

Operations Center PRO Service delivers machine health insights that help you make faster, more informed decisions, and are designed to help you stay ahead of repairs to maximize uptime. These insights are powered by telematics and backed by John Deere engineers and data scientists, who analyze data trends from connected machines and proactively surface issues before they become bigger problems. Use step-by-step guidance7 for diagnostics and repairs to help keep your operation moving.

AI-Enhanced Manual Experience – Interact with all your manuals

Manual Search with AI-Enhanced Capabilities

Manual Search with AI-Enhanced Capabilities

You’re in the field, diagnosing an issue with a machine that just went down. Instead of flipping through binders, you open Operations Center PRO Service, next you’re looking at the exact technical manual for your machine. Walking through the diagnostic steps and procedures you need to find the root cause of the problem you are experiencing.

Need to know the torque spec for a hydraulic fitting? It’s right there. Wondering if a part was updated in the latest revision? The AI Assistant highlights the change and even suggests compatible alternatives. You can ask follow-up questions like, “What’s the recommended service interval for this component?” and get an instant, AI-authored answer—no guesswork, no delays.

Having both operator and technical manuals helps ensure that everyone—from daily users to maintenance teams—has the right information to keep equipment running properly and efficiently. Operator manuals provide clear, easy-to-follow instructions for everyday use, while technical manuals offer in-depth guidance for troubleshooting, repairs, and systems. Whether you're planning a repair, training a new tech, or just brushing up on equipment details, everything is organized, searchable, and tailored to your machine.

Interactive Schematics – Look inside and see machines’ electrical systems

Easily navigate interactive schematics to help find problems fast

Easily navigate interactive schematics to help find problems fast

Your machine stops unexpectedly. Instead of flipping through manuals, you open Operations Center PRO Service and get a visual of what’s happening inside—right down to the wire.

Interactive Schematics allow you to interact with a digital version of your machines’ electrical systems (compatibility varies by model) View component-level, system- and DTC-based, and voltage supply diagrams. Trace circuits, understand how systems interact, and pinpoint the root cause of a problem faster, whether it’s a voltage drop, a faulty sensor, or a wiring issue.

- View Diagnostic Trouble Codes (DTCs): Additional connectivity hardware (Smart connector/4G Modems) required.

- Remote Software Updates: Only select controllers on machines with 4G MTG.

- Remote Diagnostics: Only on machines with 4G MTG.

- Remote Software Reprogramming: Only select controllers on machines with 4G MTG.

- Interactive Solutions: The availability of Interactive Solutions are contingent upon access to a designated set of Machine Health Insights provided through Operations Center PRO Service.

- Readings, Recording, Tests and Calibrations:

- Certain engine-related tests and calibrations are not currently available. The following tests and calibrations cannot be performed using Operations Center PRO Service:

- Liebherr

- ECU SCR Override

- DCU SCR Override

- Engine Hour Meter Calibration

- John Deere

- Aftertreatment NOx Sensor Test

- Emission Control System Derate Temporary Override

- Software Reprogramming:

- Customers can reprogram, replace, or update controllers on John Deere equipment (some third-party compatibility exclusions may apply). Depending on the machine, users can do this wirelessly with a 4G MTG Modem or wired (may require compatible cables).

- The following John Deere models contain Liebherr controllers which are not compatible and cannot be reprogrammed using Operations Center PRO Service:

- 204P, 304P, 324P Compact Wheel Loaders

- 1050J and 950J Dozers

- 9700, 9800, 9900, F9 900, and F9 1000 Self-Propelled Forage Harvesters

- At initial launch the following John Deere products contain components that cannot be reprogrammed using Operations Center PRO Service:

- Tractors with SCV valve or valve actuator replacements on the following:

- 7R and 8R

- MY2024 and newer

- MY2020 to MY2023 retrofitted

- 6R and 6M

- 6R MY18/MY22/23 - Mid and Rear

- 6M MY2018 Mid only

- 6M MY2020 and MY2025 - Mid and Rear

- MY2017 to MY2022 5R Series Tractors

- MY2001 to MY2007 5x20,6x20, and 7x20 Series tractors

- MY2001 to MY2024 1900/1910 Air Seeding Carts

- Air Seeding Tools equipped with:

- DICKEY-john® Blockage system on MY2009 to MY2021 Air Seeders

- Relative Flow Blockage systems on MY2016 to MY2022 and MY2023 to MY2025 Air Seeders

- TruSet™ Tillage Technology on MY2016 to MY2021 Air Seeders

- Planters equipped with:

- Hydraulic ground drive on MY2004 to MY2021 Planters

- SeedStar™ Gen II, SeedStar XP, or SeedStar™ 2 on MY2004 to MY2021 Planters

- Row unit controllers on MY2015 to MY2025 Planters with SeedStar™ Monitoring Systems 3, 4, or 5

- ExactRate™ Liquid Fertilizer Application System on MY2015 to MY2024

- TruSet™ Tillage Technology on MY2015 to MY2019 Tillage Equipment with

- ExactApply™ Sprayer Upgrade on MY2016 to MY2025 Sprayers