AutoTrac™Activation

- Make long days easier with equipment and technology that works together for you.

- Increase productivity by being able to cover more ground.

- Reduce overlap and maximize inputs.

- Reduce fatigue and improve operator experience

AutoTrac provides you with a hands-free guidance solution helping to manage in-field efficiency and greatly reducing operator fatigue. AutoTrac assisted steering guides the machine with accuracy in a variety of field conditions, bringing the following advantages to your operation:

Various tracking options are available with the Generation 4 AutoTrac™ guidance system, allowing you to adjust your guidance lines accordingly as you maneuver throughout different field patterns. Swap track provides you with the ability to quickly switch guidance tracks as you work through a field’s varying geographic conditions. Gen 4 AutoTrac offers the following guidance line types:

Subsequent passes are identical to the first pass

Subsequent passes are identical to the first pass

Identical subsequent passes

Identical subsequent passes

See current boundaries in a field on the display

See current boundaries in a field on the display

Set and follow tracks on the guidance run page

Set and follow tracks on the guidance run page

Gen 4 AutoTrac™ leverages the simple, modern interface offered with the Gen 4 family of displays. The following features allow both you and your machines to be more productive with AutoTrac on the Gen 4 displays:

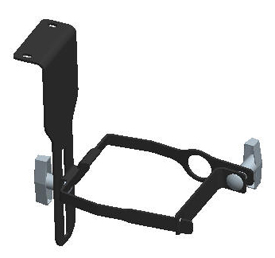

GreenStar 2 vehicle connector

GreenStar 2 vehicle connector

Machines must be GreenStar™ ready to be compatible with the AutoTrac machine kits. AutoTrac machine kits include the appropriate machine steering controller when necessary and AutoTrac-ready accessories. Display, receiver, and software to complete system sold separately.

Machines must be GreenStar™ ready to be compatible with the AutoTrac machine kits. AutoTrac machine kits include the appropriate machine steering controller when necessary and AutoTrac-ready accessories. Display, receiver, and software to complete system sold separately.

Combine vehicle kit for 70 Series

Combine vehicle kit for 70 Series

AutoTrac sprayer vehicle kit

AutoTrac sprayer vehicle kit

AutoTrac sprayer vehicle kit for 4710 models

AutoTrac sprayer vehicle kit for 4710 models

AutoTrac sprayer vehicle kit for 4720 models

AutoTrac sprayer vehicle kit for 4720 models

AutoTrac sprayer vehicle kit

AutoTrac sprayer vehicle kit

AutoTrac sprayer vehicle kit for 4920 models

AutoTrac sprayer vehicle kit for 4920 models

AutoTrac field-installed kits are now available for 6105R, 6115R, 6125R, 6140R, or 6150R MFWD Tractors.

These field-installed kits are an integrated guidance solution for John Deere 6R MFWD Tractors and are compatible with the GreenStar™ 3 or GreenStar 2 system components.

These kits contain all of the required hydraulic components and harnesses for field installation.

GreenStar display options:

StarFire™ Receiver and signal options:

AutoTrac field-installed kits are now available for 6105R, 6115R, 6125R, 6140R, or 6150R MFWD Tractors.

These field-installed kits are an integrated guidance solution for John Deere 6R MFWD Tractors and are compatible with the GreenStar™ 3 or GreenStar 2 system components.

These kits contain all of the required hydraulic components and harnesses for field installation.

GreenStar display options:

StarFire™ Receiver and signal options:

AutoTrac tractor vehicle kit

AutoTrac tractor vehicle kit

AutoTrac field-installed kits are now available for 6105R, 6115R, 6125R, 6140R, or 6150R MFWD Tractors.

These field-installed kits are an integrated guidance solution for John Deere 6R MFWD Tractors and are compatible with the GreenStar™ 3 or GreenStar 2 system components.

These kits contain all of the required hydraulic components and harnesses for field installation.

GreenStar display options:

StarFire™ Receiver and signal options:

AutoTrac field-installed kits are now available for 6105R, 6115R, 6125R, 6140R, or 6150R MFWD Tractors.

These field-installed kits are an integrated guidance solution for John Deere 6R MFWD Tractors and are compatible with the GreenStar™ 3 or GreenStar 2 system components.

These kits contain all of the required hydraulic components and harnesses for field installation.

GreenStar display options:

StarFire™ Receiver and signal options:

AutoTrac field-installed kits are now available for 6210R, 6190R, and 6170R MFWD Tractors.

These field-installed kits are an integrated guidance solution for John Deere 6R MFWD Tractors.

All required hydraulic components and harnesses for field installation are contained in these kits.

GreenStar™ display options:

StarFire™ Receiver and signal options:

The AutoTrac system reduces overlap, saving time, fuel, and labor costs. Whether breaking stubble with tillage equipment, planting or seeding, spraying or fertilizing, it reduces implement overlap by up to 90 percent. It also provides faster headland turns because the AutoTrac system takes the guesswork out of the return path.

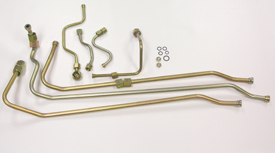

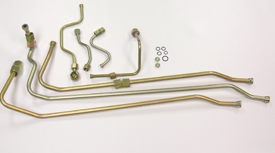

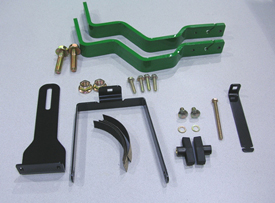

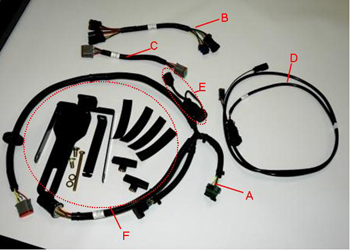

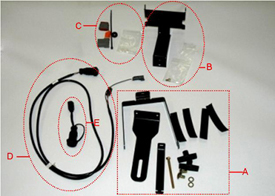

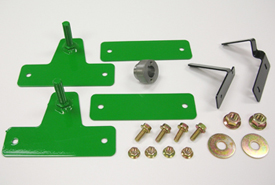

AutoTrac tractor vehicle kit items

AutoTrac tractor vehicle kit items

More AutoTrac tractor vehicle kit items

More AutoTrac tractor vehicle kit items

More AutoTrac tractor vehicle kit items

More AutoTrac tractor vehicle kit items

When paired with a StarFire™ receiver and GreenStar™ display, the integrated AutoTrac™ machine kit completes the components that automatically steer the machine. This kit is tied directly into the steering system on the machine and, therefore, provides optimum accuracy. The steering kit components cannot be moved across machine platforms.

Key features of the integrated AutoTrac steering kit:

AutoTrac tractor vehicle kit items

AutoTrac tractor vehicle kit items

More AutoTrac tractor vehicle kit items

More AutoTrac tractor vehicle kit items

More AutoTrac tractor vehicle kit items

More AutoTrac tractor vehicle kit items

AutoTrac tractor vehicle kit items

AutoTrac tractor vehicle kit items

More AutoTrac tractor vehicle kit items

More AutoTrac tractor vehicle kit items

When paired with a StarFire™ receiver and GreenStar™ display, the integrated AutoTrac™ machine kit completes the components that automatically steer the machine. This kit is tied directly into the steering system on the machine and, therefore, provides optimum accuracy. The steering kit components cannot be moved across machine platforms.

Key features of the integrated AutoTrac steering kit:

When paired with a StarFire™ receiver and GreenStar™ display, the integrated AutoTrac™ machine kit completes the components that automatically steer the machine. This kit is tied directly into the steering system on the machine and, therefore, provides optimum accuracy. The steering kit components cannot be moved across machine platforms.

Key features of the integrated AutoTrac steering kit:

When paired with a StarFire™ receiver and GreenStar™ display, the integrated AutoTrac™ machine kit completes the components that automatically steer the machine. This kit is tied directly into the steering system on the machine and, therefore, provides optimum accuracy. The steering kit components cannot be moved across machine platforms.

Key features of the integrated AutoTrac steering kit:

When paired with a StarFire™ receiver and GreenStar™ display, the integrated AutoTrac™ machine kit completes the components that automatically steer the machine. This kit is tied directly into the steering system on the machine and, therefore, provides optimum accuracy. The steering kit components cannot be moved across machine platforms.

Key features of the integrated AutoTrac steering kit:

When paired with a StarFire™ receiver and GreenStar™ display, the integrated AutoTrac™ machine kit completes the components that automatically steer the machine. This kit is tied directly into the steering system on the machine and, therefore, provides optimum accuracy. The steering kit components cannot be moved across machine platforms.

Key features of the integrated AutoTrac steering kit:

AutoTrac tractor vehicle kit

AutoTrac tractor vehicle kit

When paired with a StarFire™ receiver and GreenStar™ display, the integrated AutoTrac™ machine kit completes the components that automatically steer the machine. This kit is tied directly into the steering system on the machine and, therefore, provides optimum accuracy. The steering kit components cannot be moved across machine platforms.

Key features of the integrated AutoTrac steering kit:

When paired with a StarFire™ receiver and GreenStar™ display, the integrated AutoTrac™ machine kit completes the components that automatically steer the machine. This kit is tied directly into the steering system on the machine and, therefore, provides optimum accuracy. The steering kit components cannot be moved across machine platforms.

Key features of the integrated AutoTrac steering kit:

When paired with a StarFire™ receiver and GreenStar™ display, the integrated AutoTrac™ machine kit completes the components that automatically steer the machine. This kit is tied directly into the steering system on the machine and, therefore, provides optimum accuracy. The steering kit components cannot be moved across machine platforms.

Key features of the integrated AutoTrac steering kit:

When paired with a StarFire™ receiver and GreenStar™ display, the integrated AutoTrac™ machine kit completes the components that automatically steer the machine. This kit is tied directly into the steering system on the machine and, therefore, provides optimum accuracy. The steering kit components cannot be moved across machine platforms.

Key features of the integrated AutoTrac steering kit:

When paired with a StarFire™ receiver and GreenStar™ display, the integrated AutoTrac™ machine kit completes the components that automatically steer the machine. This kit is tied directly into the steering system on the machine and, therefore, provides optimum accuracy. The steering kit components cannot be moved across machine platforms.

Key features of the integrated AutoTrac steering kit:

When paired with a StarFire™ receiver and GreenStar™ display, the integrated AutoTrac™ machine kit completes the components that automatically steer the machine. This kit is tied directly into the steering system on the machine and, therefore, provides optimum accuracy. The steering kit components cannot be moved across machine platforms.

Key features of the integrated AutoTrac steering kit:

AutoTrac tractor vehicle kit

AutoTrac tractor vehicle kit

AutoTrac tractor vehicle kit

AutoTrac tractor vehicle kit

AutoTrac tractor vehicle kit

AutoTrac tractor vehicle kit

AutoTrac tractor vehicle kit

AutoTrac tractor vehicle kit

When paired with a StarFire™ receiver and GreenStar™ display, the integrated AutoTrac™ machine kit completes the components that automatically steer the machine. This kit is tied directly into the steering system on the machine and, therefore, provides optimum accuracy. The steering kit components cannot be moved across machine platforms.

Key features of the integrated AutoTrac steering kit:

AutoTrac tractor vehicle kit

AutoTrac tractor vehicle kit

When paired with a StarFire™ receiver and GreenStar™ display, the integrated AutoTrac™ machine kit completes the components that automatically steer the machine. This kit is tied directly into the steering system on the machine and, therefore, provides optimum accuracy. The steering kit components cannot be moved across machine platforms.

Key features of the integrated AutoTrac steering kit:

When paired with a StarFire™ receiver and GreenStar™ display, the integrated AutoTrac™ machine kit completes the components that automatically steer the machine. This kit is tied directly into the steering system on the machine and, therefore, provides optimum accuracy. The steering kit components cannot be moved across machine platforms.

Key features of the integrated AutoTrac steering kit:

AutoTrac sprayer vehicle kit for 4710 models

AutoTrac sprayer vehicle kit for 4710 models

AutoTrac SPFH base kit for ProDrive transmissions

AutoTrac SPFH base kit for ProDrive transmissions

![RowSense mechanical feelers (51-cm [20-in.] row spacing)](http://salesmanual.deere.com/sales/salesmanual/images/NA/ams/bundles/pf90699.jpg) RowSense mechanical feelers (51-cm [20-in.] row spacing)

RowSense mechanical feelers (51-cm [20-in.] row spacing)

![RowSense mechanical feelers (56-cm [22-in.] row spacing)](http://salesmanual.deere.com/sales/salesmanual/images/NA/ams/bundles/pf90700.jpg) RowSense mechanical feelers (56-cm [22-in.] row spacing)

RowSense mechanical feelers (56-cm [22-in.] row spacing)

![RowSense mechanical feelers (70-cm [27.6-in.] row spacing)](http://salesmanual.deere.com/sales/salesmanual/images/NA/ams/bundles/pf90698-1.jpg) RowSense mechanical feelers (70-cm [27.6-in.] row spacing)

RowSense mechanical feelers (70-cm [27.6-in.] row spacing)

RowSense retrofit kit for combine

RowSense retrofit kit for combine

RowSense retrofit kit for corn head

RowSense retrofit kit for corn head

AutoTrac Universal horn kit

AutoTrac Universal horn kit

AutoTrac™ is an assisted hands-free steering system that automatically steers the machine through the fields. For some of the competitive sprayers, an AutoTrac Universal Hub will be required along with other attachments. For complete compatibility information, see the ATU look up tool.

AutoTrac™ is an assisted hands-free steering system that automatically steers the machine through the fields. For some of the competitive sprayers, an AutoTrac Universal Hub will be required along with other attachments. For complete compatibility information, see the ATU look up tool.

AutoTrac™ is an assisted hands-free steering system that automatically steers the machine through the fields. For some of the competitive sprayers, an AutoTrac Universal Hub will be required along with other attachments. For complete compatibility information, see the ATU look up tool.

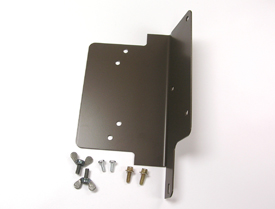

Original Greenstar display slotted bracket

Original Greenstar display slotted bracket

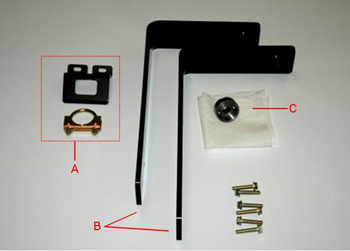

AutoTrac Universal steering supplemental kit -"A"

AutoTrac Universal steering supplemental kit -"A"

| PF90454 | Bracket, anti-rotation |

| PF80864 | Assembly, GPS bracket |

| PF12140 | Hub, spline |

| Case® IH | Row-crop | MX Maxxum® | 100/110/120/135/150/170 |

| New Holland® | Row-crop | TG | 210/230/255/285 |

| Case IH | Tracks | Quad | 375/425/450/500 |

| Case IH | 4WD | STX® | 275/325/375/425/450/500 |

| Case IH | Row-crop | MX Maxxum | 210/230/255/285 |

| Case IH | Row-crop | MX Maxxum | 180/200/220/240/270 |

| New Holland | 4WD | TJ | 275/325/75/425/450/500 |

| McCormick™ | Row-crop | ZTX | 230/260/280 |

Case, Maxxum, New Holland, and STX are U.S.-registered trademarks of CNH Global N.V. and its subsidiaries. McCormick is a trademark of McCormick International USA Incorporated.

Universal steering supplemental kit - "C"

Universal steering supplemental kit - "C"

| John Deere | Windrower | 4895/4995 | |

| John Deere | Windrower | 4990 | |

| John Deere | Windrower | 4890 | |

| Ag Chem™ | Sprayer | RoGator® | 874/1074 |

| Ag Chem | Sprayer | RoGator | 854/1054 |

| Ag Chem | Sprayer | RoGator | 664/864/1064 |

| GVM® | Sprayer | the Predator® | 9904T/1146T |

| Miller Nitro | Sprayer | 2200 Series | 200T-SS/2200T/2200HT/2200-ET |

| Miller Nitro | Sprayer | N2 Series | N2 |

| APACHE | Sprayer | 560/760/780/790/850/875/880/890/1080/1090/1280/1290 |

Ag Chem and RoGator are trademarks of AGCO Corporation. GVM and the Predator are registered trademars of GVM Incorporated.

Universal steering supplemental kit - "D"

Universal steering supplemental kit - "D"

| Ag-Chem™ | Sprayer | RoGator® | 1254/1264/1274/1274C |

| Ag-Chem | Sprayer | TerraGator® | 6103/8103/9103/9203 |

| Ag-Chem | Sprayer | TerraGator | 8104/8144 |

| New Holland®/Versatile | 4WD | 9184/9384/9484/9684/9886 | |

| GVM® | Sprayer | Prowler | 1149t |

| New Holland | Row crop | 8x70A | 8670A/8770A/8870A/8970A |

| New Holland | Row crop | 8x70 | 8670/8770/8870/8970 |

| Buhler™ | Row crop | Genesis | 2145/2160/2180/2210 |

| New Holland/Versatile | 4WD | 9282/9482/9682/9882 | |

| New Holland/Versatile | 4WD | 9280/9480/9680/9880 | |

| Buhler | 4WD | Versatile | 2290/2335/2360/2375/2425 |

| Challenger® | Tracks | MT | 835/845/855/865/875 |

| Challenger | Tracks | MT | 735/745/755/765 |

| CLAAS® | Tracks | CH | 35/45/55 |

| Case® IH | Combine | AFX | 8010 |

| New Holland | Combine | CR | 940/960/970/980 |

| New Holland | Combine | CX | 840/860/880 |

| New Holland | Windrower | HW | 300/320/340 |

| Hesston® | Windrower | 9260/9240/9230 | |

| Hesston | Windrower | 8550s/8450/8250s | |

| Challenger | Windrower | SP80/SP110/SP165 | |

| New Idea® | Windrower | 5830/5840/5850 | |

| Massey Ferguson® | Windrower | 9220/9420/220 |

Ag-Chem, RoGator, TerraGator, Challenger, Hesston, New Idea, and Massey Ferguson are trademarks of AGCO Corporation. New Holland and Case are trademarks of CNH Global N.V. and its subsidiaries. Buhler is a trademark of Buhler Industries Incorporated. CLAAS is a U.S.-registered trademark of CLAAS KGaA mbH Limited.

Universal steering supplemental kit - "E"

Universal steering supplemental kit - "E"

| AN278232 | Harness, assembly, 9986/9996 Cotton (StarFire™ receiver) |

| PF80906 | Harness, two-pin/four-pin (mini terminator) |

| PF80722 | Harness, StarFire to bulkhead |

| PF80873 | Harness, two-pin to convenience outlet |

| RE67015 | Harness, convenience outlet to power strip |

| PF90510 | Bundle, AutoTrac Universal (ATU) supplemental kit - "C" |

| John Deere | Cotton Picker | 9986/9996 |

Universal steering supplemental kit - "F"

Universal steering supplemental kit - "F"

| A | PF90510 | Bundle, ATU bracket kit "C" |

| B | AH211594 | Support, sssembly, GPS receiver |

| Not pictured | PF80722 | Harness, StarFire™ to bulkhead |

| C | PF80167 | Connector plug, StarFire |

| D | PF80873 | Harness, two-pin to convenience outlet |

| E | RE67015 | Harness, convenience outlet to power strip |

| John Deere | Self-propelled forage harvester | 7200/7300/7400/7500/7700/7800 |

AutoTrac Universal steering supplemental kit, "G"

AutoTrac Universal steering supplemental kit, "G"

| AN191704 | Clamp assembly |

| PF12372 | Bracket, anti-rotation |

| McCormick™ | Row crop | ZTX | 230/260/280 |

| Case® IH | Sprayer | SPX™ | 4410 |

| Case IH | Sprayer | FLX™ | 4010/4510 |

| Case IH | Sprayer | FLX | 3010/3510 |

| AGCO®/Willmar® | Sprayer | Eagle | 8650 |

| McCormick | Row crop | MTX | 120/135/150/165/185/200 |

| Case IH | Row crop | Maxxum® | 5220/5230/5240/5250 |

| Case IH | Sprayer | SPX | 3200/4260 |

| Case IH | Tracks | Quad | 380/430/480/530 |

McCormick is a trademark of McCormick International USA Incorporated. Case, SPX, FLX, and Maxxum are trademarks of CNH Global N.V. and its subsidiaries. AGCO and Willmar are U.S.-registered trademarks of AGCO Corporation.

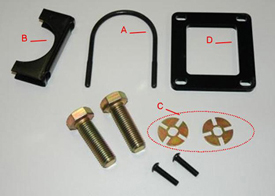

AutoTrac Universal steering supplemental kit, "H"

AutoTrac Universal steering supplemental kit, "H"

| A | PF12243 | U-Bolt |

| B | PF12244 | Saddle |

| C | PF12427 | Telescope washers |

| D | PF12442 | Bracket extension |

| Case® IH | Sprayer | SPX™ | 3150/3185/3310 |

| Case IH | Row Crop | 71x0 Magnum® | 7110/ 7120/7130/7140/7150 |

| Case IH | Row Crop | 72x0 Magnum | 7210/7220/7230/7240/7250 |

| Case IH | Row Crop | 89x0 Magnum | 8910/8920/8930/8940/8950 |

Case, SPX, and Magnum are trademarks of CNH Global N.V. and its subsidiaries.

Universal steering supplemental kit - "I"

Universal steering supplemental kit - "I"

| PF12364 | Hub, taper spline |

| PF12415 | Bracket, anti-rotation |

| RE52952 | Clamp |

| Ag-Chem™ | Sprayer | TerraGator® | 1603/1803/1903 |

| Ag-Chem | Sprayer | TerraGator | 1664/1804/1844 |

| CAT® | Tracks | E | 65/75/85/95 |

| CAT | Tracks | D | 65/75/85 |

| Caterpillar | Tracks | C | 65/70/75/85 |

| Case® IH | 4WD | Steiger® | 9310/9330/9350/9370/9380/9390 |

| Case IH | 4WD | Steiger | 91,92,9x10/9x30/9x50/9x70/9x80/9x90 |

Ag-Chem and TerraGator are trademarks of AGCO Corporation. CAT is a U.S.-registered trademark of Caterpiller Incorporated. Case and Steiger are U.S.-registered trademarks of CNH Global N.V. and its subsidiaries.

Universal steering supplemental kit - "K"

Universal steering supplemental kit - "K"

| PF12339 | Hub, taper spline |

| PF12415 | Bracket, anti-rotation |

| RE52952 | Clamp, band |

| AGCO®/Willmar® | Sprayer | Eagle | 8400/8450/8500 |

| Case® IH | Sprayer | FLX | 4275/4300/4330/4375 |

| Case IH | Sprayer | FLX | 3275/3300/3330 |

| Spra-Coupe® | Sprayer | 4000 Series | 4450/4650 |

| Spra-Coupe | Sprayer | 4000 Series | 4440/4640 |

AGCO, Willmar, and Spra-Coupe are U.S.-registered trademarks of AGCO Corporation. Case is a U.S.-registered trademark CNH Global N.V. and its subsidiaries.

AutoTrac Universal steering supplemental kit -"L"

AutoTrac Universal steering supplemental kit -"L"

| PF90510 | Bundle, ATU supplemental kit "C" |

| PF80906 | Harness, two-pin/four-pin (mini terminator) |

| PF80921 | Harness, two-pin/four-pin (large terminator) |

| PF80975 | Harness, combine, StarFire™ extension |

| PF80976 | Harness, combine, GSD Y |

| PF80722 | Harness, StarFire to bulkhead |

| AH171496 | Harness, StarFire adapter (metri-pack to Deutsch) |

| John Deere | Combine | 9x60 | 9560/8560 STS™/9660/9660 CTS™/9660 STS/9760 STS/9860 STS/9860 Premium Series |

| John Deere | Combine | 9x50 | 9450/9550/9550 SH/9650/9650 CTS/9650 STS/9750 STS |

| John Deere | Combine | 9x00/9x10 | 9400/9500/9500 SH/9600/CTS/9410/9510/9540 SH/9610/ CTS II |

Universal steering supplemental kit - "M"

Universal steering supplemental kit - "M"

| Caterpillar® | Lexion Combine | 450/465/470/475/485/460R/470R/480R (manufactured in 2002 or later) 560/560R/570R/580R/585R/590R |

Caterpillar is a U.S.-registered trademark of Caterpillar Incorporated.

Universal steering supplemental kit - "N"

Universal steering supplemental kit - "N"

| Caterpillar® | Lexion Combine | 450/465/470/475/485/460R/470R/480R (manufactured prior to 2002) |

Caterpillar is a U.S.-registered trademark of Caterpillar Incorporated.

Universal steering supplemental kit - "O"

Universal steering supplemental kit - "O"

| John Deere | Combine | 9660 WTS |

Universal steering supplemental kit - "P"

Universal steering supplemental kit - "P"

| John Deere | Cotton stripper | 7460 |

AutoTrac Universal steering supplemental kit -"Q"

AutoTrac Universal steering supplemental kit -"Q"

Universal steering supplemental kit - "R"

Universal steering supplemental kit - "R"

AutoTrac Universal steering supplemental kit-"S"

AutoTrac Universal steering supplemental kit-"S"

| John Deere | Row-crop tractor | 6x00 |

| John Deere | Row-crop tractor | 6x10 |

| John Deere | Row-crop tractor | 6x20 |

| John Deere | Row-crop tractor | 6x30 Standard Series |

| John Deere | Row-crop tractor | 7x00 Small Frame |

| John Deere | Row-crop tractor | 7x10 Small Frame |

| John Deere | Row-crop tractor | 7x20 Small Frame |

| John Deere | Row-crop tractor | 7x30 Small Frame Standard Series |

| John Deere | Row-crop tractor | 7xx0 HI Crop |

AutoTrac Universal steering supplemental kit -"T"

AutoTrac Universal steering supplemental kit -"T"

| John Deere | Sprayer | 4700 |

| John Deere | Sprayer | 4x10 |

| John Deere | Sprayer | 4x20 |

| John Deere | Row-crop tractor | 8x00 |

| John Deere | Row-crop tractor | 8x10 |

| John Deere | Row-crop tractor | 8x20 |

| John Deere | Row-crop tractor | 8x30 |

| John Deere | Row-crop tractor | 7x20 large frame |

| John Deere | Row-crop tractor | 7x30 large frame |

| John Deere | 4WD tractor | 9x00 |

| John Deere | 4WD tractor | 9x20 |

| John Deere | 4WD Tractor | 9x30 |

Universal steering supplemental kit - "U"

Universal steering supplemental kit - "U"

Universal steering supplemental kit - "V"

Universal steering supplemental kit - "V"

Universal steering supplemental kit - X

Universal steering supplemental kit - X

GreenStar 2 third-party controller kit

GreenStar 2 third-party controller kit

GreenStar 2 vehicle connector

GreenStar 2 vehicle connector

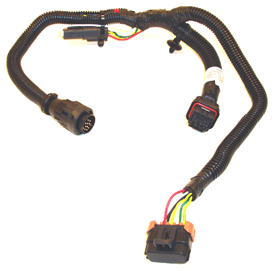

Harness for Field Doc Connect

Harness for Field Doc Connect

GreenStar ISO implement

GreenStar ISO implement

Right-hand console

Right-hand console

Stand-alone harness

Stand-alone harness

GreenStar desktop bundle

GreenStar desktop bundle

35-ft extension harness

35-ft extension harness

GreenStar 2 to Orginal GreenStar vehicle connector harness

GreenStar 2 to Orginal GreenStar vehicle connector harness

Machine specific kits provide dealers with all of the hardware and harnessing to equip your 2410C or 2510H with dry applicator with AccuFlow Vortex Cooler minus:

Auxiliary-power extension harness

Auxiliary-power extension harness

Center extension harness

Center extension harness

Center extension harness

Center extension harness

High-current power-adapter harness

High-current power-adapter harness

High-current power-adapter harness

High-current power-adapter harness

High-current power-extension harness

High-current power-extension harness

High-current extension harness

High-current extension harness

Switch and power extension harness

Switch and power extension harness

Rear extension harness

Rear extension harness

Surface water implement mast

Surface water implement mast

Surface Water Pro receiver mounting kit

Surface Water Pro receiver mounting kit

Moisture sensor conversion kit

Moisture sensor conversion kit

Combine moisture sensor retrofit kit on 50 Series

Combine moisture sensor retrofit kit on 50 Series

First introduced in 1995, Combine Yield Monitoring and Combine Yield Mapping were John Deere’s first precision farming products. It is capable of monitoring or mapping yield and moisture on many of the older John Deere combines as field-installed attachments.

Harvest Monitor™ and Harvest Doc™ – 9060 Series Combines

*Harvest Monitor and Harvest Doc is retrofittable to 50 Series Combines

Functionality includes multi-client functionality, boundary recording, and weather and field condition recording as well as compatibility to GreenStar™ guidance products.

Harvest Monitor enables the operator to view yield and moisture while harvesting. It consists of the following components:

Harvest Doc enables the operator to record yield and moisture with GPS and later load the information into desktop software as maps and reports. To upgrade from Harvest Monitor to Harvest Doc, the following additional components are necessary:

StarFire™ Receiver

First introduced in 1995, Combine Yield Monitoring and Combine Yield Mapping were John Deere’s first precision farming products. It is capable of monitoring or mapping yield and moisture on many of the older John Deere combines as field-installed attachments.

Harvest Monitor™ and Harvest Doc™ – 9060 Series Combines

*Harvest Monitor and Harvest Doc is retrofittable to 50 Series Combines

Functionality includes multi-client functionality, boundary recording, and weather and field condition recording as well as compatibility to GreenStar™ guidance products.

Harvest Monitor enables the operator to view yield and moisture while harvesting. It consists of the following components:

Harvest Doc enables the operator to record yield and moisture with GPS and later load the information into desktop software as maps and reports. To upgrade from Harvest Monitor to Harvest Doc, the following additional components are necessary:

StarFire™ Receiver

First introduced in 1995, Combine Yield Monitoring and Combine Yield Mapping were John Deere’s first precision farming products. It is capable of monitoring or mapping yield and moisture on many of the older John Deere combines as field-installed attachments.

Harvest Monitor™ and Harvest Doc™ – 9060 Series Combines

*Harvest Monitor and Harvest Doc is retrofittable to 50 Series Combines

Functionality includes multi-client functionality, boundary recording, and weather and field condition recording as well as compatibility to GreenStar™ guidance products.

Harvest Monitor enables the operator to view yield and moisture while harvesting. It consists of the following components:

Harvest Doc enables the operator to record yield and moisture with GPS and later load the information into desktop software as maps and reports. To upgrade from Harvest Monitor to Harvest Doc, the following additional components are necessary:

StarFire™ Receiver

First introduced in 1995, Combine Yield Monitoring and Combine Yield Mapping were John Deere’s first precision farming products. It is capable of monitoring or mapping yield and moisture on many of the older John Deere combines as field-installed attachments.

Harvest Monitor™ and Harvest Doc™ – 9060 Series Combines

*Harvest Monitor and Harvest Doc is retrofittable to 50 Series Combines

Functionality includes multi-client functionality, boundary recording, and weather and field condition recording as well as compatibility to GreenStar™ guidance products.

Harvest Monitor enables the operator to view yield and moisture while harvesting. It consists of the following components:

Harvest Doc enables the operator to record yield and moisture with GPS and later load the information into desktop software as maps and reports. To upgrade from Harvest Monitor to Harvest Doc, the following additional components are necessary:

StarFire™ Receiver

First introduced in 1995, Combine Yield Monitoring and Combine Yield Mapping were John Deere’s first precision farming products. It is capable of monitoring or mapping yield and moisture on many of the older John Deere combines as field-installed attachments.

Harvest Monitor™ and Harvest Doc™ – 9060 Series Combines

*Harvest Monitor and Harvest Doc is retrofittable to 50 Series Combines

Functionality includes multi-client functionality, boundary recording, and weather and field condition recording as well as compatibility to GreenStar™ guidance products.

Harvest Monitor enables the operator to view yield and moisture while harvesting. It consists of the following components:

Harvest Doc enables the operator to record yield and moisture with GPS and later load the information into desktop software as maps and reports. To upgrade from Harvest Monitor to Harvest Doc, the following additional components are necessary:

StarFire™ Receiver

First introduced in 1995, Combine Yield Monitoring and Combine Yield Mapping were John Deere’s first precision farming products. It is capable of monitoring or mapping yield and moisture on many of the older John Deere combines as field-installed attachments.

Harvest Monitor™ and Harvest Doc™ – 9060 Series Combines

*Harvest Monitor and Harvest Doc is retrofittable to 50 Series Combines

Functionality includes multi-client functionality, boundary recording, and weather and field condition recording as well as compatibility to GreenStar™ guidance products.

Harvest Monitor enables the operator to view yield and moisture while harvesting. It consists of the following components:

Harvest Doc enables the operator to record yield and moisture with GPS and later load the information into desktop software as maps and reports. To upgrade from Harvest Monitor to Harvest Doc, the following additional components are necessary:

StarFire™ Receiver

First introduced in 1995, Combine Yield Monitoring and Combine Yield Mapping were John Deere’s first precision farming products. It is capable of monitoring or mapping yield and moisture on many of the older John Deere combines as field-installed attachments.

Harvest Monitor™ and Harvest Doc™ – 9060 Series Combines

*Harvest Monitor and Harvest Doc is retrofittable to 50 Series Combines

Functionality includes multi-client functionality, boundary recording, and weather and field condition recording as well as compatibility to GreenStar™ guidance products.

Harvest Monitor enables the operator to view yield and moisture while harvesting. It consists of the following components:

Harvest Doc enables the operator to record yield and moisture with GPS and later load the information into desktop software as maps and reports. To upgrade from Harvest Monitor to Harvest Doc, the following additional components are necessary:

StarFire™ Receiver

First introduced in 1995, Combine Yield Monitoring and Combine Yield Mapping were John Deere’s first precision farming products. It is capable of monitoring or mapping yield and moisture on many of the older John Deere combines as field-installed attachments.

Harvest Monitor™ and Harvest Doc™ – 9060 Series Combines

*Harvest Monitor and Harvest Doc is retrofittable to 50 Series Combines

Functionality includes multi-client functionality, boundary recording, and weather and field condition recording as well as compatibility to GreenStar™ guidance products.

Harvest Monitor enables the operator to view yield and moisture while harvesting. It consists of the following components:

Harvest Doc enables the operator to record yield and moisture with GPS and later load the information into desktop software as maps and reports. To upgrade from Harvest Monitor to Harvest Doc, the following additional components are necessary:

StarFire™ Receiver

First introduced in 1995, Combine Yield Monitoring and Combine Yield Mapping were John Deere’s first precision farming products. It is capable of monitoring or mapping yield and moisture on many of the older John Deere combines as field-installed attachments.

Harvest Monitor™ and Harvest Doc™ – 9060 Series Combines

*Harvest Monitor and Harvest Doc is retrofittable to 50 Series Combines

Functionality includes multi-client functionality, boundary recording, and weather and field condition recording as well as compatibility to GreenStar™ guidance products.

Harvest Monitor enables the operator to view yield and moisture while harvesting. It consists of the following components:

Harvest Doc enables the operator to record yield and moisture with GPS and later load the information into desktop software as maps and reports. To upgrade from Harvest Monitor to Harvest Doc, the following additional components are necessary:

StarFire™ Receiver

First introduced in 1995, Combine Yield Monitoring and Combine Yield Mapping were John Deere’s first precision farming products. It is capable of monitoring or mapping yield and moisture on many of the older John Deere combines as field-installed attachments.

Harvest Monitor™ and Harvest Doc™ – 9060 Series Combines

*Harvest Monitor and Harvest Doc is retrofittable to 50 Series Combines

Functionality includes multi-client functionality, boundary recording, and weather and field condition recording as well as compatibility to GreenStar™ guidance products.

Harvest Monitor enables the operator to view yield and moisture while harvesting. It consists of the following components:

Harvest Doc enables the operator to record yield and moisture with GPS and later load the information into desktop software as maps and reports. To upgrade from Harvest Monitor to Harvest Doc, the following additional components are necessary:

StarFire™ Receiver

Today’s producers demand more and with GreenStar™ technology and John Deere delivers. With GreenStar components, customers have the ability to document and map harvest data, create prescriptions, set field boundaries and more. This translates to better management practices, better yields, and more profit.

Harvest Doc Cotton

The Harvest Doc Cotton yield mapping system from John Deere Ag Management Solutions (AMS) gives cotton producers the ability to see harvest data right from the cab. Using yield data collected by the machine, detailed cotton yield maps can be generated in Apex™ Farm Management software to help producers make more informed decisions.

Harvest Doc Cotton-ready machines are equipped with mass-flow sensors that monitor cotton flow through the machine’s air ducts. This information is then sent to the display in the cab for operator viewing.

Machine compatibility:

For Harvest Doc Cotton functionality, the following GreenStar components are also needed:

NOTE: Harvest Doc Cotton-ready machines are equipped with mass-flow sensors and associated brackets, cab signal combiner module (SCM), StarFire receiver bracket, GreenStar 2/GreenStar 3 mounting bracket, and lightbar adapter harness.

GreenStar displays

The GreenStar 3 2630 Display provides the operator with a number of items, including lint yield, load weight, GPS and recording status, cotton variety, area, and distance covered. All of this information can be compiled within the Harvest Doc Cotton system.

The GreenStar 3 2630 Display is fully compatible with both the 7760 and 7660.

StarFire receivers

StarFire receivers help producers track in-field productivity using GPS and GLONASS satellite signals.

In Harvest Doc Cotton, StarFire receivers' georeference yield data is captured by the mass flow sensors. This information is transferred to the cab display, which can then give operators yield data relative to field position.

To accommodate a wide range of accuracy needs and to offer unmatched upgradeability, the StarFire 3000 Receiver is available in different configurations: SF1 and SF2 ready.

Apex Farm Management software

In the office, Apex Farm Management software is used to generate detailed yield data.

The cotton yield map from Apex shows yield variance throughout the field. Also, printed on the map is the total number of acres harvested, harvest date, average yield, and harvest hours for the operator, farm, and field.

AutoTrac SPFH base kit for non-ProDrive

AutoTrac SPFH base kit for non-ProDrive

AutoTrac SPFH controller for 7000 and 7050 Series

AutoTrac SPFH controller for 7000 and 7050 Series